Solar-Powered Warehouses Cut Energy Costs by 60% (Real Results Inside)

Transform your warehouse into a sustainable powerhouse with solar technology that’s revolutionizing the industrial landscape. Modern warehouses consume massive amounts of energy for lighting, climate control, and operations – but industrial solar lighting solutions and comprehensive solar power systems are changing the game. Forward-thinking facility managers are slashing energy costs by up to 75% while shrinking their carbon footprint through strategic solar installations.

Picture vast rooftop spaces converted into clean energy generators, powering everything from automated sorting systems to electric forklifts. This isn’t just about going green – it’s about smart business. With federal tax incentives at an all-time high and installation costs at historic lows, warehouse solar projects typically pay for themselves within 5-7 years while providing decades of reliable, renewable energy.

Join the thousands of distribution centers and logistics hubs already harnessing the sun’s power to drive operational efficiency and sustainability. Whether you’re managing a small storage facility or overseeing a massive fulfillment center, solar technology offers scalable solutions that grow with your business while protecting your bottom line.

Why Solar Lighting Makes Perfect Sense for Warehouses

The Cost-Saving Potential

The financial benefits of solar-powered warehouses are substantial and measurable. Businesses can significantly reduce energy costs by up to 75% after installation, with many facilities reporting complete return on investment within 5-7 years.

Consider a typical 50,000-square-foot warehouse that spends $60,000 annually on electricity. Installing a solar power system could reduce this expense to approximately $15,000 per year, resulting in $45,000 in annual savings. While the initial investment might range from $200,000 to $400,000, federal tax incentives and local rebates can offset up to 30% of installation costs.

Additional savings come from reduced maintenance needs and longer equipment lifespans due to consistent power supply. Many warehouse operators report decreased HVAC costs as solar panels provide natural roof insulation. The system’s 25-30 year lifespan ensures long-term cost benefits, with most installations paying for themselves multiple times over during their operational lifetime.

Smart energy management systems further optimize these savings by automatically adjusting power consumption based on real-time needs and solar generation patterns.

Environmental Impact

Solar-powered warehouses significantly reduce their environmental footprint by tapping into clean, renewable energy. A typical warehouse conversion to solar power can eliminate hundreds of tons of carbon dioxide emissions annually – equivalent to taking dozens of cars off the road. The environmental benefits extend beyond carbon reduction, as solar installations help decrease dependence on fossil fuels and reduce local air pollution.

These sustainable warehouses contribute to better air quality in industrial areas and demonstrate corporate environmental responsibility. By generating clean energy on-site, businesses minimize their grid reliance and support local energy independence. The solar panels’ long lifespan of 25-30 years ensures decades of sustainable operation with minimal environmental impact.

Additionally, solar-powered warehouses often incorporate other eco-friendly features like LED lighting and energy-efficient HVAC systems, creating a comprehensive approach to sustainability. Many facilities also participate in local environmental initiatives, sharing excess power with the community grid and setting an example for other businesses to follow. This ripple effect helps accelerate the transition to renewable energy across the industrial sector.

Essential Components of a Solar Warehouse Lighting System

Solar Panels and Collection Systems

Modern solar panel systems for warehouses typically feature either monocrystalline or polycrystalline panels, with monocrystalline being the more efficient but costlier option. These panels are strategically installed on the warehouse roof, usually at a 30-degree angle to maximize sun exposure throughout the day.

When planning a solar installation, warehouse owners should first assess their roof’s structural integrity and available space. A typical warehouse roof can accommodate enough panels to generate 100-500 kilowatts of power, depending on its size. The installation process involves mounting rails, securing panels, and connecting them to inverters that convert DC power to usable AC electricity.

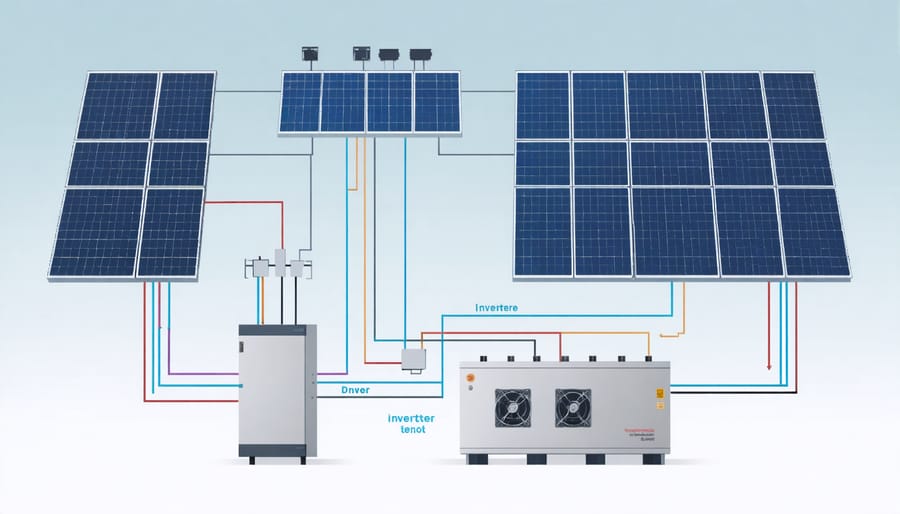

Collection systems include essential components like:

– Solar panels (typically 60 or 72-cell commercial modules)

– Inverters (string or microinverters)

– Mounting hardware

– Power optimizers

– Monitoring systems

Weather conditions and geographical location play crucial roles in panel placement. For instance, warehouses in snowy regions might require steeper panel angles, while those in high-wind areas need additional mounting reinforcement.

Many warehouse owners opt for bifacial panels, which can capture reflected sunlight from light-colored roofing materials, increasing energy production by up to 5-15%. Smart monitoring systems help track performance and quickly identify any maintenance needs, ensuring optimal energy collection throughout the system’s 25-30 year lifespan.

Battery Storage Solutions

Battery storage systems are essential components of any solar-powered warehouse, ensuring continuous operations even when the sun isn’t shining. Modern lithium-ion batteries have become the go-to choice for commercial installations, offering superior performance and longer lifespans compared to traditional lead-acid batteries.

A well-designed storage solution typically includes multiple battery banks working together to store excess energy generated during peak sunlight hours. These systems can power your warehouse operations during cloudy days, nighttime, or grid outages. Most commercial installations opt for storage capacity that can support 24-48 hours of critical operations.

Smart battery management systems (BMS) help optimize energy storage and usage by monitoring battery health, managing charging cycles, and automatically switching between power sources. These intelligent systems can prioritize certain operations during power limitations and ensure optimal battery performance throughout their lifespan.

When selecting a battery storage solution, consider factors like:

– Daily energy consumption needs

– Peak load requirements

– Available space for battery installation

– Climate control requirements

– Future expansion plans

– Backup power duration requirements

Many warehouse operators are now choosing modular battery systems, which allow for easy scaling as energy needs grow. These systems can be expanded without disrupting existing operations, providing flexibility for future growth while maintaining initial cost efficiency.

Remember to include regular maintenance in your battery storage planning, as proper care can significantly extend the system’s lifespan and maintain optimal performance.

Smart Implementation Strategies

Optimal Placement and Layout

The strategic placement of solar panels and lighting fixtures is crucial for maximizing the efficiency of your solar-powered warehouse. For optimal solar panel performance, start by analyzing your roof’s orientation – south-facing surfaces in the Northern Hemisphere receive the most sunlight throughout the day. Ensure panels are installed at a 30-45 degree angle, depending on your geographical location, to capture maximum solar energy.

When planning your lighting layout, divide your warehouse into zones based on activity levels and natural light availability. Place motion sensors in less frequently used areas to conserve energy, and position LED fixtures to create overlapping light patterns that eliminate dark spots. Install skylights strategically to complement your artificial lighting system during daylight hours.

Consider the height of storage racks and equipment when designing your lighting plan. Higher ceilings typically require more powerful fixtures mounted at specific intervals to ensure even illumination. Create a primary lighting grid for general illumination and supplement with task lighting in areas requiring detailed work or specific light levels.

Remember to keep solar panels clear of shade from nearby structures or trees, and plan for regular maintenance access. Install monitoring systems at ground level for easy tracking of system performance. By following these placement guidelines, you can achieve up to 30% better energy efficiency compared to randomly placed systems.

Integration with Existing Systems

Integrating solar power into your existing warehouse infrastructure doesn’t have to be complicated. Modern smart solar integration systems are designed to work seamlessly with conventional electrical setups, making the transition smooth and efficient.

Start by conducting an energy audit to identify your current lighting patterns and power requirements. This helps determine the optimal solar system size and configuration for your needs. Next, install solar panels on your warehouse roof or adjacent ground space, connecting them to power inverters that convert DC power to AC.

The key to successful integration lies in the hybrid controller system, which automatically switches between solar and grid power as needed. During daylight hours, your warehouse runs primarily on solar energy, while the grid serves as a backup during cloudy days or nighttime operations.

Consider implementing a phased approach to minimize disruption to your operations. Begin with lighting systems, then gradually expand to power other warehouse equipment. Modern control systems allow you to monitor energy usage in real-time and adjust settings for maximum efficiency.

Remember to maintain your existing electrical infrastructure during the transition – it serves as a crucial backup system and ensures continuous operations during maintenance or unexpected weather conditions.

Maintenance Requirements

Regular maintenance is crucial for keeping your solar-powered warehouse operating at peak efficiency. A well-maintained system not only lasts longer but also delivers consistent energy savings throughout its lifetime. Here’s what you need to know about keeping your solar installation in top shape.

Schedule professional inspections twice a year to check for any damage to solar panels, wiring, and inverters. These inspections should include thorough testing of all electrical connections and monitoring system performance. To maintain solar lighting performance, clean the panels quarterly or more frequently in dusty areas.

Keep detailed maintenance logs and monitor your system’s daily output through your management software. Any unexpected drops in performance should be investigated promptly. During winter months, ensure panels are clear of snow and debris. Consider installing automated cleaning systems for larger installations to reduce manual maintenance needs.

Check weather sealing and mounting hardware annually to prevent water damage and ensure structural integrity. Replace inverters every 10-15 years and monitor battery systems (if installed) for optimal charging cycles. Train your facility staff on basic maintenance procedures and establish clear protocols for reporting issues.

Remember that while solar systems are generally low-maintenance, regular upkeep is essential for maximizing your return on investment and ensuring long-term reliability.

Real-World Success Stories

The IKEA distribution center in Perryville, Maryland stands as a shining example of solar-powered warehouse success. After installing a massive 2.6-megawatt solar array across their 1.7 million square foot facility in 2019, they’ve reduced their annual energy costs by 71% and eliminated over 3,000 tons of carbon emissions yearly. The project paid for itself in just under four years through energy savings and tax incentives.

In California, the Prologis warehouse complex showcases how solar power can transform large-scale operations. Their Oakland facility, spanning 1 million square feet, implemented a comprehensive solar system in 2018 that now generates 110% of their energy needs. The excess power is fed back into the local grid, creating an additional revenue stream while supporting community sustainability.

Tesla’s Gigafactory in Nevada demonstrates how solar power can integrate seamlessly with advanced manufacturing. Their 5.8 million square foot facility operates entirely on renewable energy, with solar panels covering the entire roof space. The installation has helped Tesla reduce operational costs by approximately $2.5 million annually while maintaining 24/7 production capabilities.

A smaller yet equally impressive example comes from Family Food Distributors in Arizona. Their 50,000-square-foot cold storage facility faced astronomical energy bills due to constant refrigeration needs. After installing solar panels in 2020, they’ve cut their electricity costs by 65% and maintained consistent temperature control even during peak summer months.

The success of these implementations highlights key factors for achieving optimal results: proper system sizing, strategic panel placement, and integration with existing building management systems. Each facility also reported additional benefits beyond energy savings, including improved worker comfort through better temperature regulation, enhanced corporate image, and increased property value.

These success stories demonstrate that solar-powered warehouses aren’t just environmentally responsible – they’re smart business investments that deliver measurable returns while future-proofing operations against rising energy costs.

The transition to solar-powered warehouses represents a significant step forward in sustainable business operations. As we’ve explored throughout this article, the benefits extend far beyond environmental impact. From substantial cost savings and increased energy independence to enhanced property value and improved corporate image, solar power offers a compelling solution for modern warehouse operations.

The technology has matured significantly, making solar installations more efficient and affordable than ever before. With various financing options available and potential tax incentives, the initial investment hurdle has become much more manageable for businesses of all sizes.

Whether you’re managing a small storage facility or overseeing a massive distribution center, solar power can be tailored to meet your specific needs. The success stories and case studies we’ve discussed demonstrate that solar-powered warehouses are not just a future possibility – they’re a present reality delivering tangible results.

Take the first step toward solar adoption today by consulting with qualified solar installers and energy experts. The path to sustainable warehouse operations is clear, and the time to act is now.